Minolta Hi-Matic F: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

There are at least two versions of this camera, with differences in the circuit board and in the charge gear ratchet (at top). | === General notes === | ||

There are at least two versions of this camera, with differences in the circuit board and in the charge gear ratchet (at top). | |||

There's no meter movement - an IC converts the light level from the LDR into a shutter delay via a small solenoid. | |||

There's one left-hand threaded screw. It's the main wind-on lever gear at the right side of the camera when the bottom cover is off, with a thin flat-head drive. | There's one left-hand threaded screw. It's the main wind-on lever gear at the right side of the camera when the bottom cover is off, with a thin flat-head drive. | ||

[[File:Shutter geartrain.jpg | |||

Corrosion of steel contacts seems to be a common problem for the two examples I've seen so far. | |||

=== Disassembly === | |||

As usual for cameras of this type, you need to take the charge lever and the rewind crank off to remove the top cover. The charge lever has a screw top with spanner holes underneath the leatherette. The rewind crank just screws off by turning it anticlockwise. Once the covers and leatherettes are off, the baseplate assembly comes off in one piece by disconnecting all the wires (2 at the bottom need to be unfolded from hiding spots and desoldered, some of the wires at the top are connected to contacts that can be demounted by one screw or an e-clip) and removing the 4 screws. | |||

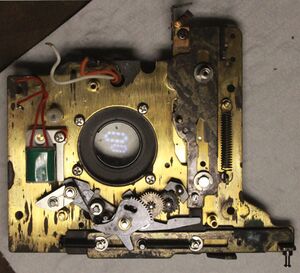

[[File:Shutter geartrain.jpg|thumb|Arrangement of shutter timing gears on the back of the baseplate.|none]]There is a plastic riser implanted in the baseplate, underneath the right-hand end of the shutter charging shuttle (bottom right in the above image). This is pressed into the plate - don't remove it unless you have to. It's brittle and may not survive being re-inserted. If you have to re-insert it, then you will definitely need to taper out the top of the hole at little bit so that the plastic will go back in. Otherwise it'll simply refuse to fit. and break. | |||

A note about the small spring that rests against one of the shutter charge shuttle is mounted over: when this spring is in its correct position, it can be hard to get the gears to sit still while you put the PCB back on top, and they have a tendency to jump out of position. You CAN move the tip of the spring back to the post to the right of it, which takes a lot of the spring pressure off of it. Then once the PCB is back on, you can access the end of the spring with needle-nose pliers from the edge of the sandwich to move it back to the correct place again. | |||

Revision as of 04:34, 23 April 2025

General notes

There are at least two versions of this camera, with differences in the circuit board and in the charge gear ratchet (at top).

There's no meter movement - an IC converts the light level from the LDR into a shutter delay via a small solenoid.

There's one left-hand threaded screw. It's the main wind-on lever gear at the right side of the camera when the bottom cover is off, with a thin flat-head drive.

Corrosion of steel contacts seems to be a common problem for the two examples I've seen so far.

Disassembly

As usual for cameras of this type, you need to take the charge lever and the rewind crank off to remove the top cover. The charge lever has a screw top with spanner holes underneath the leatherette. The rewind crank just screws off by turning it anticlockwise. Once the covers and leatherettes are off, the baseplate assembly comes off in one piece by disconnecting all the wires (2 at the bottom need to be unfolded from hiding spots and desoldered, some of the wires at the top are connected to contacts that can be demounted by one screw or an e-clip) and removing the 4 screws.

There is a plastic riser implanted in the baseplate, underneath the right-hand end of the shutter charging shuttle (bottom right in the above image). This is pressed into the plate - don't remove it unless you have to. It's brittle and may not survive being re-inserted. If you have to re-insert it, then you will definitely need to taper out the top of the hole at little bit so that the plastic will go back in. Otherwise it'll simply refuse to fit. and break.

A note about the small spring that rests against one of the shutter charge shuttle is mounted over: when this spring is in its correct position, it can be hard to get the gears to sit still while you put the PCB back on top, and they have a tendency to jump out of position. You CAN move the tip of the spring back to the post to the right of it, which takes a lot of the spring pressure off of it. Then once the PCB is back on, you can access the end of the spring with needle-nose pliers from the edge of the sandwich to move it back to the correct place again.